Manufacturing products need to be labeled. A fast and reliable rate of labeling guarantees the avail

Manufacturing products need to be labeled. A fast and reliable rate of labeling guarantees the availability of goods. The more efficient the rate of labeling the more the industry becomes successful. Label applicator machines will be best in applying labels on any surface of products.

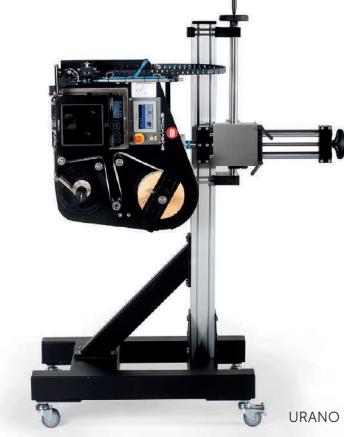

Applicator for labels machines are used to apply automatically labels that are pre-printed on it to the final product's surface. Large, medium as well as small-sized businesses in a general use label applicator machine. It has standard labels but specially designed labels can be designed and customized as required. It can be used to print labels on the surface of bottles, cans containers, containers, cardboard boxes, plastic packaging, pallets and other items. It is widely employed in the pharmaceutical industry, bakeries, dairy and dairy, and food and beverages industries, making it easier to maintain quality of the items across all distribution outlets as it ensures uniform application every time, it can be cost-effective and cuts costs on labor. The label applicator makes industrial tasks easier. These labels applicators remove the manual process of label application or double handling, as well as long work hours. As a result, products can be supplied to consumers at lower prices. Applicator for labels has two functions, one of which is multifunctional ability. Popular applications include bottles made of plastic, metal and glass containers, corrugated cardboard, paper and fibreboard packaging wooden, cardboard tubes, and various other plastic or wood containers.

Thermal Transfer Over printers (TTO) have been usually installed on labelers that print information that is variable directly on the label right before applying to products that are moving along an assembly line. A label application system that is automated can be integrated into a batch coderor thermal inkjet printer or a printing engine. These optional coding printers vary from printing single line, double line, or a large dimensions label. If you require a bigger print size the print engine must be utilized one of the following: Zebra, Datamax and Sato Print width of these print engines varies between 4 and 6 inches which permits you to print larger size prints. Print engines with these names can print SSCC labels, or larger labels that contain information about the product, ingredients, nutritional panel barcode, QR code expiry date, etc.

The label application machines can be operated with ease and require a minimal maintenance. This makes them more robust and cost-effective to label applicator. Faster speed and quality labeling make the machine more widely used by many companies.

In accordance with the type of business and product Customers can select a variety of different label applicator equipment. Our team of experts is always available to assist you make the right decision. We will help you make the right choice and recommend the best item with precisely the specifications to satisfy the requirements of your.